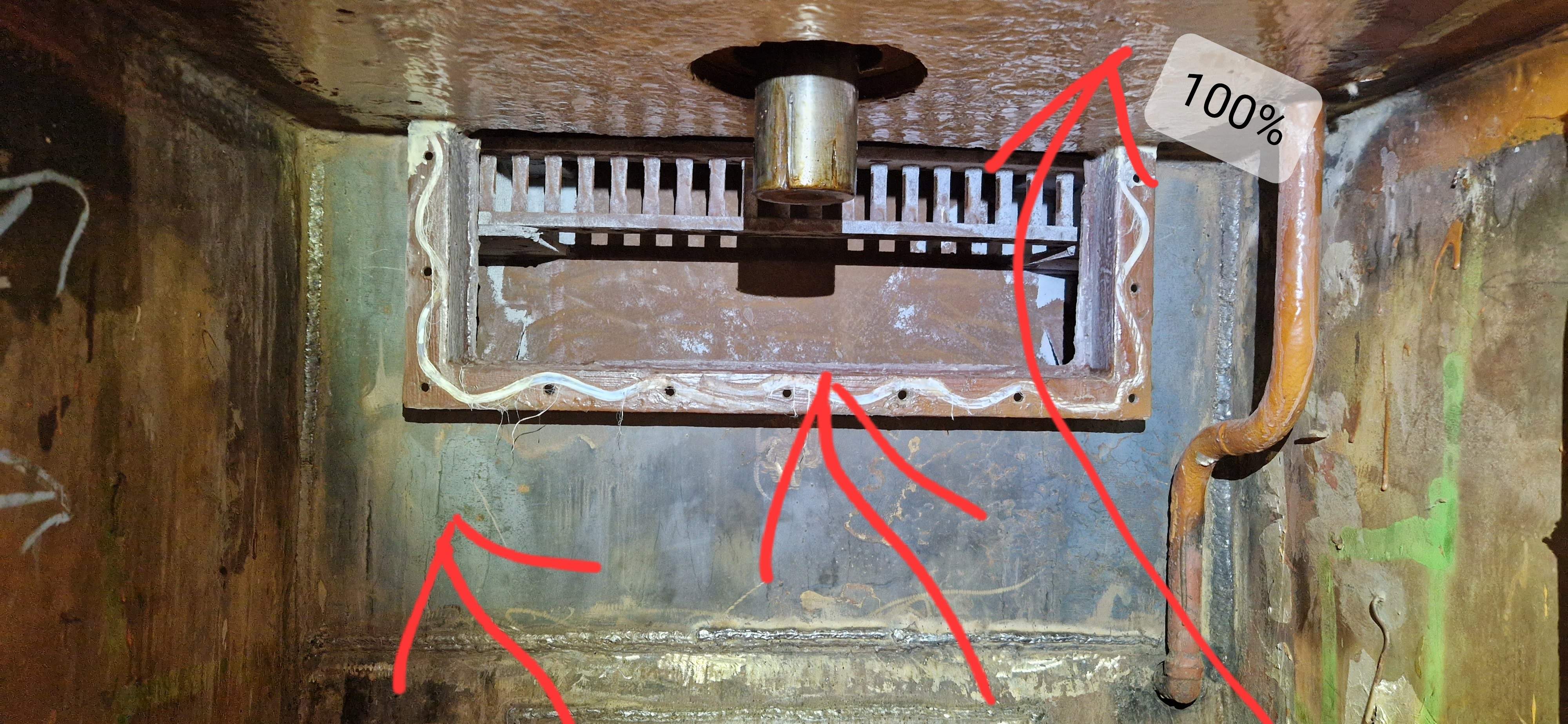

During maintenance shutdowns of each plants, Cor Team acts on behalf of the investor - power plant, waste incineration plant, plant industry or the oil & gas industry and works in its interest, is to available 24/7. During the investment, he supervises and verifies the work of companies with anti-corrosion industry, performing quality and technical acceptances. Ongoing supervision of local repairs damage to anti-corrosion coatings enables reduction of repair costs, guarantees that the work will be carried out in accordance with DIN standards and manufacturer's recommendations, use appropriate

repair technology, shortening the downtime of the installation. The entire supervision process repair extends the coating life cycle, optimizes the number man-hours allocated to individual processes, provides the Investor with a current one access to photographic documentation and analysis of progress in the aspect previously presented by the contractor of the schedule. Any discrepancies or threats to the schedule are immediately reported to the Investor to whom we advise the best solutions, taking into account DIN standards and practice engineering.

© Cor Team Tomasz Dziaduszewski 2023